Founded in Rome, Carbonikon operates at the intersection of design and material science, applying aerospace-grade carbon fibre engineering to the luxury accessories market. The company’s roots in aeronautical manufacturing inform its commitment to structural performance, product longevity and lightweight design. Rather than rely on aesthetics alone, Carbonikon’s handbags and briefcases are positioned as long-term assets that combine industrial-grade precision with practical utility. By focusing on resilience and efficiency over seasonal trends, the brand challenges traditional notions of luxury and offers a performance-driven alternative for discerning consumers. With growing interest in high-performance materials within the luxury segment, Carbonikon’s approach aligns innovation with sustainability and measurable value.

Many of Carbonikon’s products have registered copyrighted designs. The company’s mission is to offer objects that reflect the feeling and passion for their work. “Our creations are part of us and our family who actively participate in their conception and creation,” says Fabio Manieri, Company Owner of Aviacompositi – Carbonikon. LUXUO speaks to Manieri on how the brand is translating aeronautical innovation into the language of luxury.

Your bags made of carbon are truly unique! Tell us about your passion for carbon, which is usually a material associated with the aerospace and automotive sectors?

My passion for carbon fibre stems from my passion for aeroplanes and their technologies. Having grown up in Ciampino, where Rome’s second airport is located, it’s easy to imagine why. My passion for aeroplanes and all the technologies applied to them dates back to when I was very young. I started building model aeroplanes at the age of five, and as I grew up I built all kinds of them. My passion for aeroplanes led me to attend the G. Galilei aeronautical construction school in Rome. In 1985, studying in even greater depth, I decided to build my own two-seater ultralight aircraft. I designed the aerodynamics and the structure and built it over three years of intense work. After many tests, I took it for a flight in 1988. I had realised my dream! I later took my wife, my father and many friends up for flights. It’s incredible to think that I built it in the family Woodshop, which was located on ‘Wright brothers’ street! It seemed like a sign of destiny…

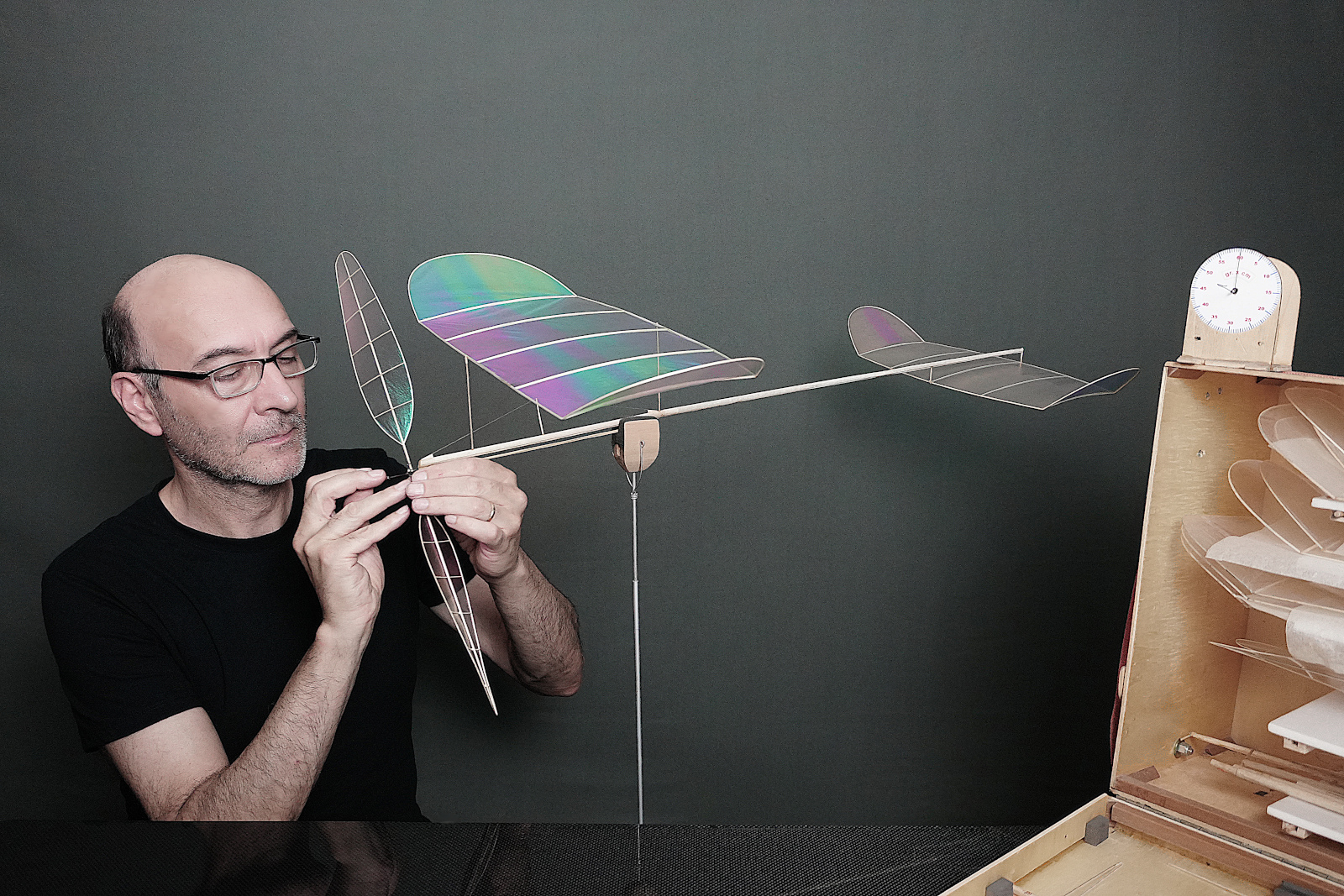

Many years later, from 2001 to 2018, I resumed my old passion for model aeroplanes, winning 18 consecutive Italian championships in the “FAI” (Fédération Aéronautique Internationale) F1D and F1M categories, Ministick and TH are endurance model aeroplanes weighing between 0.49 grams and 3 grams (this is not a mistake; they really weigh between 0.49 and 3 grams depending on the category). They fly on their own without radio control and with a rubber band motor. They are extreme in their construction and aerodynamics, and even have an automatic variable pitch propeller, built as if it were part of a watch! If well built and set up, F1Ds, which represent the top of the category, can fly for almost half an hour in a single flight. They are extremely efficient and represent the essence of flight physics. This is an ancient category of model aeroplanes that embodies all the modern concepts of lightness and energy saving, which are the same reasons why carbon fibre is used today.

Returning to carbon fibre, from 1988 to 1992 my passion led me to work at Agusta helicopter company in the composite materials plant, where I was employed in the experimental composite materials department and in the industrial engineering office, thus increasing my specialisation in these materials that I already knew. During those years, carbon fibre began to be used in other sectors as well, and I constantly followed its development. In fact, around 1992, after leaving Agusta, I began to manufacture model aircraft parts and motorcycle parts in carbon fibre. In 1998, I founded Aviacompositi, which for 27 years has been producing many carbon fibre parts for the automotive sector as well as for many research and development sectors.

One of the most important and unusual projects I have personally undertaken was the design and construction of the carbon fibre support for the statue of Apollo Belvedere for the Vatican Museums. It was a very challenging project that took me over eight months to design and build. The Apollo, a statue created around 150 AD by the Romans, is a landmark and icon of classical sculpture. It was once again shown to the world last October after five years of restoration. The video of the restoration, which also shows me installing the carbon support, can be viewed on YouTube.

Tell us about the unique properties of carbon?

The main properties of carbon fibre are its high mechanical strength and stiffness, compared to its low weight, which, when properly exploited, offer great advantages. Its low weight allows for significant energy savings. For example, in transport, many commercial aircraft make extensive use of carbon fibre. Being lighter, they consume less fuel, resulting in lower costs and less impact on pollution. As a general concept of high performance and maximum efficiency, just think of Formula 1 cars or America’s Cup boats.

You stated that the Carbonikon bags you have created are not just accessories, but style statements that reflect the harmony between form and function. Can you elaborate there?

Carbonikon bags and accessories are not just beautiful objects in themselves. When I design them, I don’t just think about their form, but also their practical everyday use. I believe they should bring satisfaction and lighten our days, not only by being beautiful objects to look at, giving us that feeling of enchantment we get when we look at a work of art, but also by having a practical use. For me, this is the concept of perfect balance between aesthetic form and functionality.

Why is the lightness of carbon a key element of differentiation for your bags?

It is the same concept of energy efficiency expressed above: lightness reduces energy consumption for us too, as we tire less easily. It is better to have a lightweight container which, when added to the load to be carried, has the lowest possible weight. For example, our empty briefcase weighs about 1 kg (2.20 lbs) less than a standard one, which means that when full, it will weigh on average the same as or less than a normal empty briefcase. The same concept is applied to the women’s handbag that weights only 380 grams (0.84 lb).

Do you see yourself as an engineer or a fashion designer, or both?

Considering my passion for technology, my many interests, passions and studies – from aeronautics to mechanics, design, electronics, computer science, photography and so on – I believe I am a multifaceted engineer with an innate sensitivity to design and the beauty of things. This is not meant to be self-celebration, but rather a thoughtful reflection on a life devoted to pursuing my passions.

At Carbonikon, traditional craftsmanship meets technological precision. Tell us about the production process.

The production process for a carbon fibre component is very long and complex. There are stages where modern technology can be used, but there are also many stages where high-level craftsmanship and skills are required. For example, in the design phase, we move from pencil drawings to 3D CAD, and to create the mould, the model is normally milled using CNC, but in some cases it may be more convenient to do it by hand using the traditional method. To make the product, the carbon must be layered in the mould entirely by hand, and this is where human skill makes all the difference. To achieve a high-quality aesthetic effect, the fibres must be layered very carefully without distortion or asymmetrical orientation.

Then, in the finishing stage, there is a whole phase of manual sanding, followed by painting, which gives the carbon beauty and durability, and mirror polishing in the case of a glossy finish. The process is as long and complex as that of painting a supercar. in addition to this, taking our women’s bag or briefcase as an example, there is also the preparation and manual sewing of the inner lining, its gluing to the carbon shells, the gluing of the closing frames, the assembly of the handles and bottom studs, all very long and delicate manual operations that, when done skilfully, really make the difference.

What is the profile of your clientele and what do they look for when purchasing a Carbonikon bag?

Our customers seek the uniqueness of an object, its soul that carries with it a part of us, our passion for what we do and my personal history in the world of technology and design. Ours is a modern customer who appreciates the combination of technology and refinement, loves exclusivity and personalisation, and knows that the product they are buying is not a sterile industrial production but a product with a history, the result of the passion of people who have dedicated their lives to seeking excellence in their work.

You argue that a product that lasts over time is more sustainable. Can you tell us what you think about this?

Fast fashion certainly produces more pollution due to the large quantities produced, which generates a large amount of waste to be treated. My vision is of a product that lasts over time without ending up in a landfill after a few months. At Carbonikon, we apply this concept to everything we do, and it also represents our concept of quality, which translates into a benefit for both the planet and the customer.

Do you use recycled materials?

Where possible, we always try to use materials with a very low environmental impact, such as water-based mould release agents and so on. At the same time, we try to optimise production processes to minimise energy consumption.

Do you create limited series?

Yes, we plan to create limited series and unique pieces of our products.

Where do you see your brand in five years? Will you operate a network of Carbonikon boutiques?

I see steady growth towards the main global markets. At the moment, we operate directly through our online shop, but growth will most likely lead us to create a network of Carbonikon boutiques.

What is your definition of success?

For me, success means having people appreciate what we do. Of course, it also means seeing Carbonikon grow in terms of reputation and popularity around the world and knowing that many people identify with our style. Success in economic terms is obviously important, but for me it comes after these things.

If you were to name one person or mentor who has inspired you along your life and career, who would that be?

Both for inspiration and gratitude, to my father who was so creative in his work, called “Archimedes” by his friends, who passed on to me his passion for invention and ingenuity, to my mother too with her conviction that my creative activities and passions would help me in life. I think they were both absolutely right, to my wife Antonella, who has always stood by me and supported me in my work for many years, physically making our products with me and contributing her ideas and creativity which met mine as well; to my daughters, with whom I often discuss things, listening to their points of view and advice. They are all true sources of inspiration and guiding lights in my life.

For more information on Carbonikon, click here.

For more on the latest in leaders, style and fashion reads, click here.